Pores and cracks in the metallic glasses prepared by laser powder bed fusion

作者:Haishun Liu a , Yangyang Jiang a , Dengfeng Yang a , Qi Jiang a , Weiming Yang b 时间:2023-08-26 点击数:

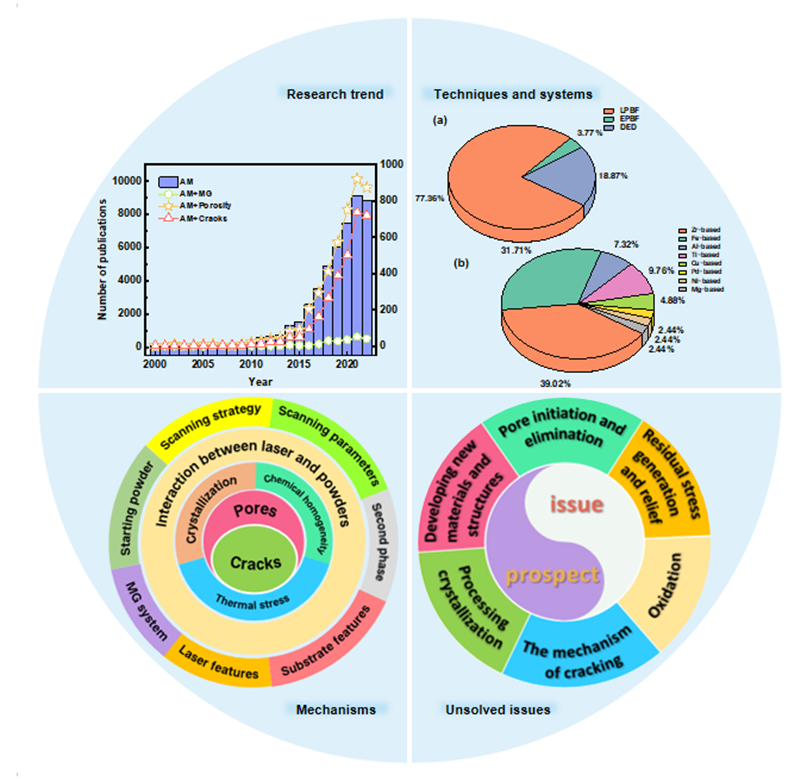

The rapidly developing additive Manufacturing (AM) technology could overcome the critical dimension limit of metallic glasses (MGs). This permits to obtain MG components with complex geometry and large dimensions. However, the residual defects, such as pores and cracks in AMed MGs, significantly deteriorate their performance. Thus, it is essential to suppress and eliminate the pores and cracks that remain after additive manufacturing.

This paper critically reviews the pores and cracks in the laser powder bed fusion (LPBF) fabricated MGs, including recent achievements and challenges in depressing their initiation, alleviating their propagation, and eliminating their collapse.The recent advances in LPBFed MGs and the suppression strategies of pores and cracks, such as parameters optimization,scanning strategy alteration, second phase's introduction, substrate and MG system selection as well as components performance improvement with designed porosity, are reviewed and commented, especially for several specific MG systems. The pores and cracks initiation and alleviation mechanisms are further analyzed. Also, the unsolved issues, challenges, and future research directions are evaluated. Finally, concluding remarks and an outlook concerning the pores and cracks issues in LPBFed MGs are further provided.

文章链接:Pores and cracks in the metallic glasses prepared by laser powder bed fusion - ScienceDirect