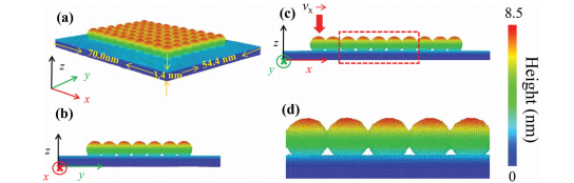

As a promising additive manufacturing technique, selective laser melting (SLM) provides the possibility of fabricating metallic glassy components free of the constraints of geometrical complexity and dimensions. However, unexpected crystallization greatly affects the microstructure and degrades the mechanical performance of SLM-fabricated metallic glasses (MGs). To clarify the crystallization mechanism and the effect of laser processing on the crystallization, we investigate the atomic-level crystallization in the SLM Zr90Cu10 MG by using molecular dynamics simulations. The results show that crystallization highly related to scan speed lies in the atomic-level cluster changes. Lower scan speed leads to a dramatically increased fraction of the BCC crystal phase, accompanied by the nucleation of a few HCP and FCC crystal phases. As scan speed increases, more icosahedron-like clusters are formed, leading to the formation of the MG, while the nucleation of the crystal phase is suppressed. The suppression of crystallization is further attributed to a higher average temperature variation rate induced by higher scan speed, which reduces the relaxation time, preventing the nucleation and growth of crystal phases. This work contributes to the understanding of the crystallization in MGs during the SLM process at the atomic level, providing guidance to suppress the crystallization in the SLM process of desired metallic glassy components.

文章链接:Physical Chemistry Chemical Physics, 2019, 21: 12406. (SCI一区)