近日,由中国矿业大学材料与物理学院刘海顺教授、张响教授领衔的非晶合金催化研究团队,联合深部岩土力学与地下工程国家重点实验室,在工业铁基非晶带材催化降解苯酚研究领域取得重要进展。课题组研究生张杰作为第一作者完成的论文《Simultaneously improved kinetic rate and reusability in phenol degradation by laser processing on Fe-based amorphous ribbon》发表于国际权威期刊《Journal of Non-Crystalline Solics》。研究首次系统揭示了激光表面处理同步提升铁基非晶带材催化活性与循环稳定性的内在机制,为难降解有机污染物的高效治理提供了全新技术路径。

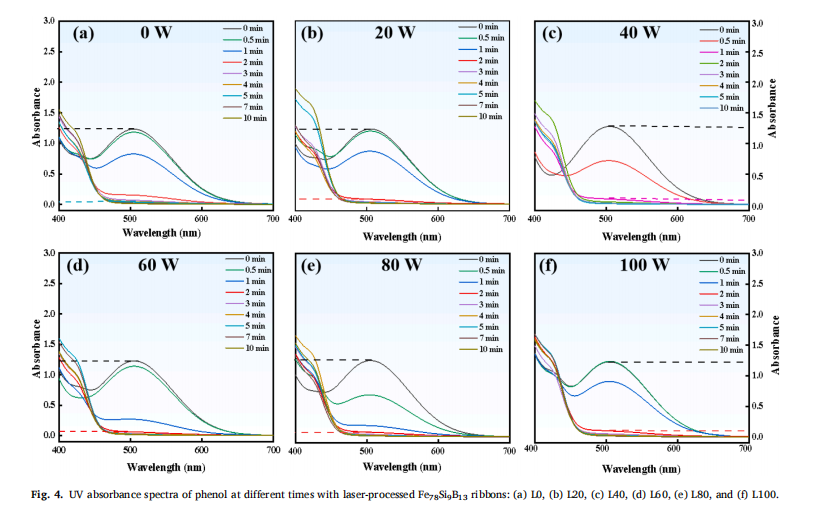

The metastable energy state and abundant active sites in Fe-based amorphous alloys (FAAs) make them promising catalysts. Surface atomic states may affect the catalytic performance of FAAs, in addition to their internal long-range disordered atomic structure. This paper investigates how laser surface processing affects the phenol degradation performance of industrial Fe₇₈Si₉B₁₃ amorphous ribbon. Appropriate laser processing significantly improves phenol degradation performance. In particular, 40 W laser processing leads to the most pronounced improvement in kinetic rate, reaching 0.82 min⁻¹—much higher than that of previous Fe-based catalysts, even at lower catalyst dosage. Moreover, the degradation rate remains above 98% after 18 cycles. The enhanced degradation is attributed to lower activation energy, abundant active sites, and increased ·OH generation under suitable laser processing. This study reports improved phenol degradation performance of Fe-based amorphous ribbon via laser processing and reveals the underlying mechanisms, providing a feasible strategy for developing efficient and durable FAA catalysts for treating phenol-containing wastewater.

论文链接:https://doi.org/10.1016/j.jnoncrysol.2025.123812